The northwest corner of St. Clair Avenue West and Weston Road in Toronto is home to a 600,000 square foot big box retail centre called The Stockyards. The site is a part of a large redevelopment project that consists of the construction of multiple commercial retail units in two levels and a three-storey parking garage. The site had been historically used to raise livestock, process meat and related products after being used as landfill from 1920 to 1950.

The geotechnical investigations required ground improvement due to poor soil conditions and the loading configuration. As an alternative to costly large scale excavation and replacement, Menard (formerly Geopac), which is a subsidiary of the Soletanche Freyssinet Group (similar to RECo), proposed a value-engineering solution utilizing Dynamic Compaction (DC), Rapid Impact Compaction (RIC), and Controlled Modulus Columns (CMC), to improve the upper 6-15 meters of fill materials on this challenging project.

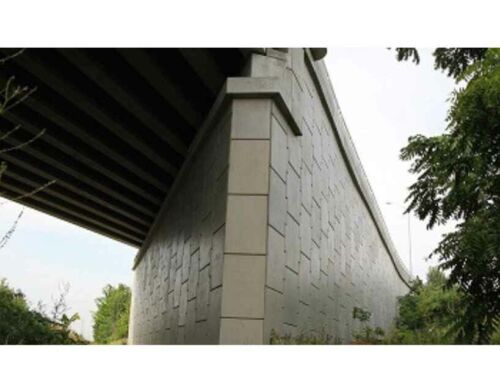

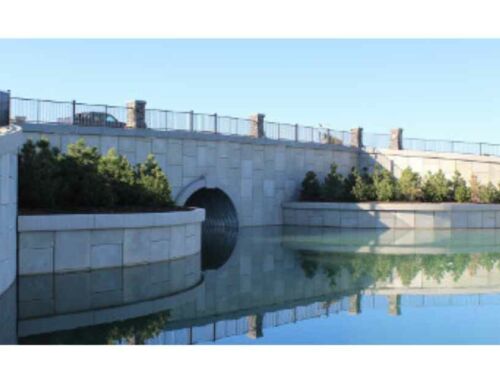

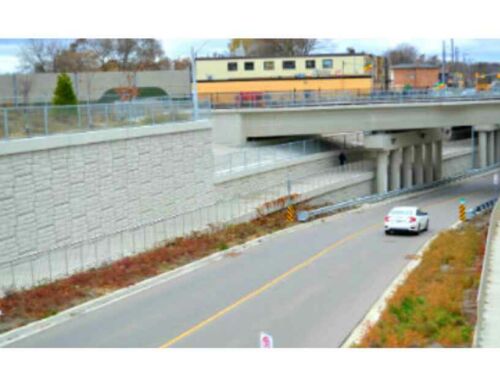

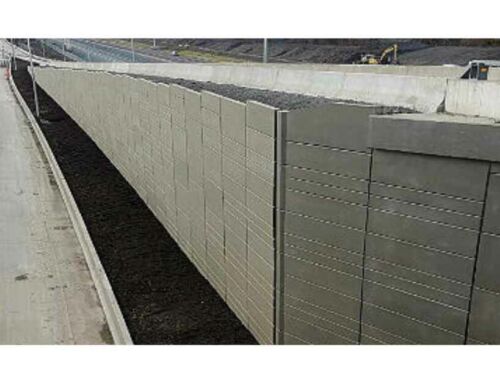

The site grading plan required retaining walls to retain the backfill and support the footings of commercial buildings and the parking structure along Weston Road, Gunns Road as well as the north entrance ramp. The project consultant proposed mechanically stabilized earth (MSE) walls to a maximum height of about 9 meters. Reinforced Earth Company Ltd. (RECo) was awarded the project that included the design and supply of a 2300m2 vertical facing Reinforced Earth (RE) retaining wall with precast TerraClass panels and high adherence steel strip soil reinforcements. The ground improvement work was designed and carried out by Menard. This affiliation provides clients with innovative and cost-effective solutions that are offered within one group.

In the north and northeast of the site, with a commercial retail unit only one and a half meters behind the wall, Menard and RECo planned to utilize CMC’s to support the retaining wall and use a preload of 30 kPa after wall construction to induce the initial settlements before the building is constructed. The wall in this section is 7 m high and the CMC’s are to a maximum depth of 9 meters. Sharing the same parent company played a big role in securing this project and this project is the first of many synergy projects between RECo and Menard across Canada.

The subsurface investigation indicates a heterogeneous fill at the site and further investigation identified a thick layer of soft to firm silty clay fill right underneath the northeast retaining wall. Spacing, diameter and depth of the inclusions were defined to respect a maximum settlement of 25 mm.

The approach in the design of load bearing MSE walls is developed from an extensive research in modeling, testing, field instrumentation, and the verification of material behavior versus design theory, uniform analytical design procedures based on finite element analysis. This method is confirmed and supported by measurements from earlier structures which allows the design of load-supporting RE in the project and enables analysis of external loads from superstructure footings.

Prime considerations in the design of this type of load bearing walls are the bearing capacity, the load distribution, and tolerance to settlement and horizontal deflections. The flexibility of the facing enables the RE wall to better withstand movements in the vertical, horizontal and longitudinal directions. Accordingly this type of wall is suitable to withstand the internal settlement and foundation movements due the preloading suggested in this section of the wall.

The arching effects from the CMC may cause differential settlement and add stresses to the lower strips at the base of the RE wall. In order to mitigate the additional stress, a load transfer platform (LTP) was considered. The LTP distributes the CMC axial loads to soil reinforcements and eliminates the local stress on the first layer of steel strips. The LTP consists of a compacted granular fill with 100% compaction and about 1 meter thickness that is placed between the top of CMCs and the first layer of soil reinforcement.

A monitoring system was implemented to regularly observe the movements of MSE wall after wall construction and during different stages of loading. In order to do that, reflective targets were placed on the facing panels in defined intervals. Targets were monitored for a total duration of 6 months prior to the building construction. According to the monitoring results, the settlement of the wall was in the range of 15 to 20 mm under the surcharge. Horizontal displacement readings also showed a fairly uniform movement of the wall face, approximately 22 mm without any tilting. Monitoring readings are consistently lower than the range calculated in finite element analysis. Based on the results of post-construction monitoring, it was concluded that no significant wall movement has occurred.