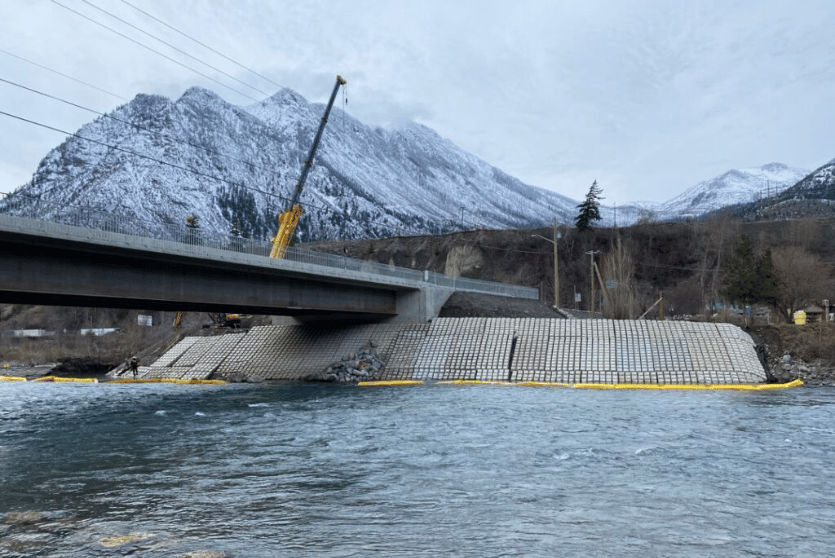

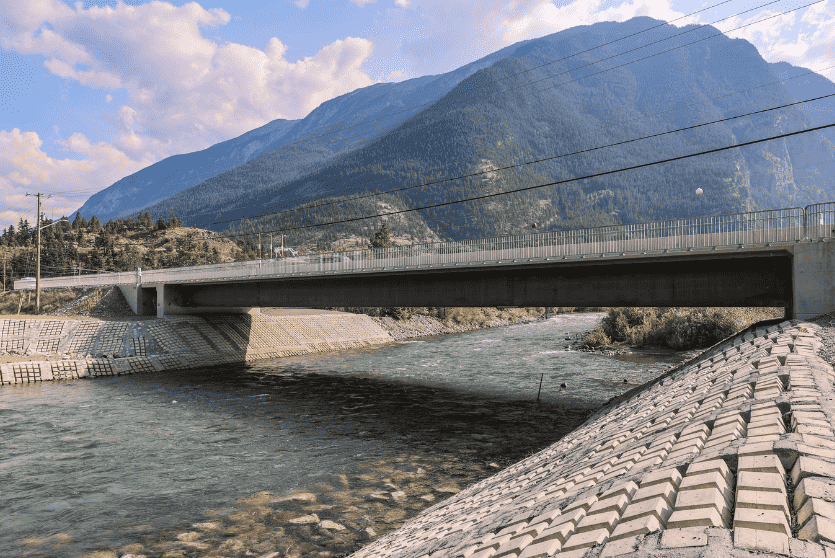

Cable Concrete®, an Articulating Concrete Block (ACB) system

For meeting erosion control design needs, Cable Concrete stands out as a reliable choice. This technology is engineered to be better than loose rock, offering a superior solution for effective erosion control. Reinforced Earth Company Ltd. and IECS Group Inc. have entered into a strategic collaboration agreement aimed at promoting the widespread adoption of Cable Concrete® technology across the Western provinces of Canada.

Cable Concrete®, a signature innovation

Crafted as a versatile alternative to loose rock rip rap, Cable Concrete® stands out as an Articulating Concrete Block (ACB) system interlinked by cables, allowing each block to flex and adapt to the natural terrain. With six available thickness options, this interconnected block system ensures economical stability tailored to the unique requirements of each project.

Extensively tested by engineering departments at four distinguished universities—; The University of Colorado; and The University of Minnesota; The University of Windsor, Ontario; & The University of Western Ontario, Ontario. As well as full scale testing at various industry leading research facilities. —Cable Concrete® has proven its reliability and efficacy.

Where Cable Concrete is Used

Cable Concrete finds primary application in soil erosion control, offering a cutting-edge solution for sustainable engineering practices. Key applications include:

- Riverbank Protection

- Culvert Inlet/Outlet Protection

- Spillways

- Channel Lining

- Pond Lining

- Pipeline Protection

- Lagoon Protection

- Low Water Crossings

- Dam Overflow/Intakes

- Access Roads

- Overflow/Weirs

- Boat Ramps

Why Choose Cable Concrete

- Cost-Effective: It’s a budget-friendly solution for erosion control.

- Swift Installation: Precast mats with preattached geotextile make for quick and quality installation.

- Engineered: To deliver assured performance

- Low Maintenance: Easily maintained when covered with vegetation or rocks.

- Durable: Resistant to ice damage, freeze-thaw cycles & debris flood events.

- Adaptable: Conforms to existing ground contours, minimizing site preparation.

- Reusable: Mats can be removed and used on future projects.

- Quality Assurance: Locally manufactured to rigorous specifications, exceeding material requirements.

Key Features of Cable Concrete

- Large Mats: Quick and economical installation with large concrete mats.

- Durability: Made with air-entrained concrete for freeze-thaw resistance.

- Cable Looping: Cables looped on all four sides of mat edges for connection and optional anchoring.

- Open Area: 20-40% open area for water permeability and vegetation growth.

- Articulation: Pyramidal block shape allows articulation (20° to 60°).

- Engineering Validation: Comprehensive analysis and testing by reputable universities.

Benefits

Stability

Stability

Integrated cables allow easy interlocking for a strong unit, recommended for high flow and steep slope applications.

Flexibility

Flexibility

Design ensures uniform pressure on geotextile and subgrade material for maximum effectiveness in erosion control.

Versatility

Versatility

Can be easily cut to fit smaller areas, irregular shapes, and accommodate drainage pipes, manholes, etc.

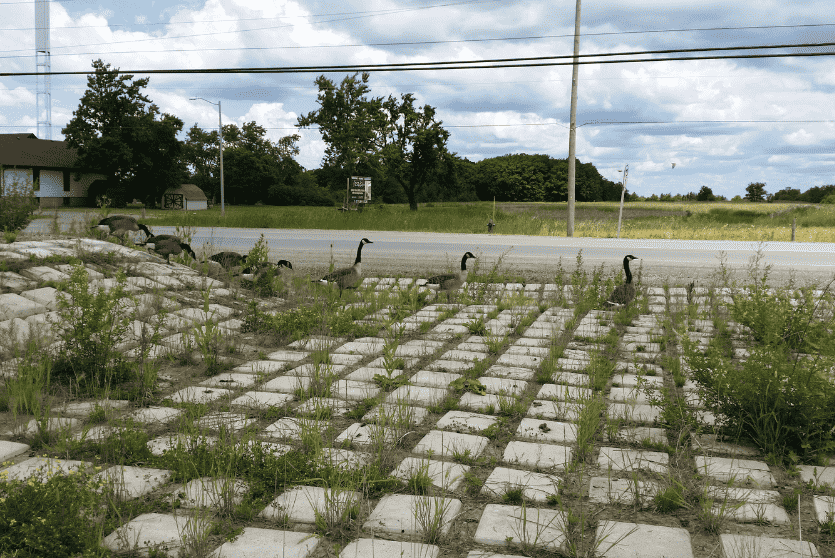

Vegetation Regrowth

Vegetation Regrowth

Open area facilitates vegetation regrowth; backfilling and seeding recommended for optimal results.

Anchoring

Anchoring

Integrated cable provides extra stability, supporting earth anchors and/or tow-in options.

Vehicle Access

Vehicle Access

Allows even distribution of external forces, making it suitable for constructing vehicle crossings over creek and river beds.

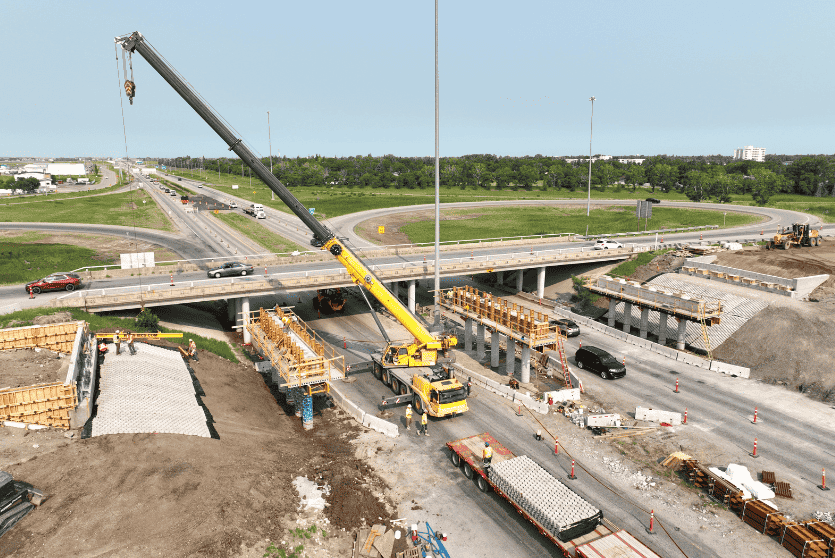

Installation

Installation

Exceptionally easy to install above and below water level, with on-site assembly not required, minimizing labor costs.

Pipeline Protection

Pipeline Protection

IECS offers a range of concrete mattresses for comprehensive pipeline protection on land or underwater.