1. Tensile Forces at the connection are a function of the facing stiffness.

2. Any connection that requires a lot of effort by the contractor is prone to improper assembly and uneven transfer of loads. For that reason, a good connection must be easily connected during construction.

3. Soil reinforcement with multiple connection points has potential for uneven loading and must be carefully designed to account for this challenge.

4. When welded wire steel has been cold worked by drawing, deforming, bending to 90 degrees and then hot dipped galvanized, this can result in cracks in the steel forming at the bend which can cause strain-age embrittlement that accelerates rapidly under the temperature range used in the zinc bath in the hot dipped galvanization process. This type of embrittlement can lead to failure of the connection.

5. The Charpy V-notch Impact Test is a viable test method to determine if steel is brittle, which might lead into a connection failure.

6. The connection should contain an adequate amount of ductility and redundancy to overcome unexpected loading conditions in the field.

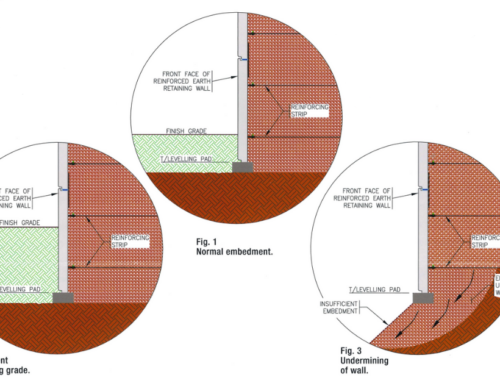

7. There are several items that should be implemented to reduce the down drag force on connections caused by internal consolidation of the backfill:

• Proper degree of compaction of internal backfill along with site quality control.

• Use of compressible rubber pads in every horizontal joint.

• Supplier’s specification details which show fill to be placed with no void under the connection/soil reinforcement.

• Site quality control to ensure proper backfilling under connection.

8. An additional way to provide more ductility is by choosing hot rolled structural steel for both the connector and soil reinforcement, over other types of steel.